ANALYSIS OF THERMAL EFFECT

Thermal Conductivity (I, W/m*K)

Thermal conductivity is often the most recognized and referenced thermal property of a material.

It is a bulk or absolute property meaning it does not change with the size or shape of the material.

A sheet of rubber 0.1 mm thick has the same thermal conductivity as a sheet of the same rubber 10 mm thick.

Thermal conductivity is defined as the time rate of heat flow, under steady state conditions, through unit area,

per unit temperature gradient in the direction perpendicular to the area.

Thermal Resistance (R, m2*K/W)

The thermal resistance is defined as the opposition a material presents to the flow of heat.

Thermal resistance can provide the designer with more information than thermal conductivity

for products with defined dimensions, such as thermal insulators or adhesives sold in sheets or as die cut parts.

The resistance can be calculated from the thermal conductivity so long as we know the distance

over which we want to know the resistance.

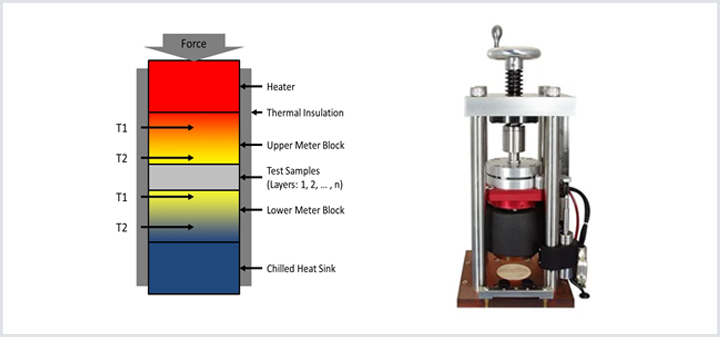

Determination by ASTM D5470 Test Method

ASTM D5470 utilizes a stacked fixture to create an assumed 1-dimensional heat flow through a sample.

Thermal impedance is calculated for several thicknesses by measuring the power dissipation and temperature difference from

one side of the sample to the other. Plotting the thicknesses against the thermal impedances produces a straight line

whose formula contains the thermal conductivity, thermal resistance, and contact resistance.

Please contact us for any detailed information or specific needs.

Please contact us for any detailed information or specific needs.