RELIABILITY TEST

Test sample

- HTPCM350P

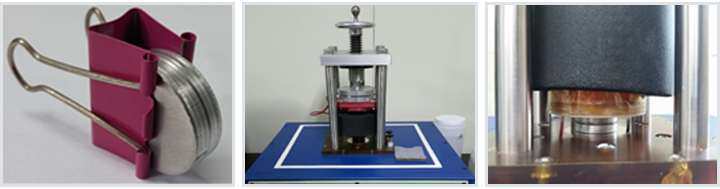

Preparation of test sample

1. Spread HTPCM350P on aluminum plate measuring 100㎛ thickness and dry for four hours at 60℃ then leave

for 12hrs at room temperature

2. Place another aluminum plate on top of the test sample so that the sample maintain between two round

aluminum plate.

3. Test the sample for 10min using TIM tester under 70℃@20psi condition.

4. Leave the sample for 1hr at room temperature(20~25℃).

5. Test thermal resistance of sample (℃-in2/W)

6. Hold the test sample using clamps to hold a constant pressure on the sample

※ Prepare 39EA (Before Test 3EA, High Temperature Test 12EA, HAST Test 12EA, Thermal Shock Test 12EA)

1. Test equipment : TIM TESTER (Analysis Tech / USA)

2. Spec : ASTM D5470

3. Test Sample Temp @50℃

4. Pressure 10~60psi

5. Reference : Thermal resistance value of aluminum plates without sample

※ Apply 200pcs silicone oil(Wacker sil-gel 650A) at each end of the stacked two aluminum plates to minimize

the surface resistance deviation then test the thermal resistance

TEST METHOD

High Tempearature Test

• Leave the sample in high temperature thermal chamber for 1,000hr at 150℃

• Sampling each 240hr (240hr, 480hr, 720hr, 1,000hr)

• Leave the sample for 24~48hr at room condition(23±3℃ , 45±15%) and check Thermal Resistance

• Test Items

• Thermal Resistance (TIM TESTER / Analysis Tech USA / ASTM D5470)

Highly Temperature And Humidity Stress Test

• Leave the sample in temperature and humidity chamber for 1,000hr at 85℃/ 85%humidity

• Sampling each 240hr (240hr, 480hr, 720hr, 1,000hr)

• Leave the sample for 24~48hr at room condition(23±3℃ , 45±15%) and test individual test items

• Test Items

• Same as high temperature test items

Thermal Shock Test

• 40℃ (20min) → 120℃ (20min) → -40℃ (20min) 500cycle / Ramp up/Ramp Down : 5second

• Sampling each 125cycle

• Leave the sample for 24~48hr at room condition(23±3℃ , 45±15%) and test individual test items

• Test Items

• Same as high temperature test items

TEST RESULT

High Tempearature Test

• Decrease thermal resistance( Better thermal performance)

• Change range reduces after 720hr and almost no change is showed in thermal resistance after 480hr

Highly Temperature And Humidity Stress Test

• Decrease thermal resistance( Better thermal performance)

• Steep degradation until 720hr then gradual degradation is showed

Thermal Shock Test

• Decrease thermal resistance( Better thermal performance)

• Change range is relatively small

Please contact us for any detailed information or specific needs.

Please contact us for any detailed information or specific needs.